Preamble:

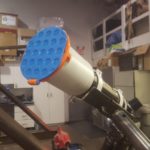

At the last minute, I purchased a sheet of Baader Planetarium solar film for the eclipse on Monday. With little time to spare, the film was taped to a cardboard box and slid over my telescope. Prayers were made that the wind wouldn’t blow the film off of the scope, and the next day I decided to build a proper holder for the expensive film – $100 CAD for an 8″ x 11″ sheet!

Project:

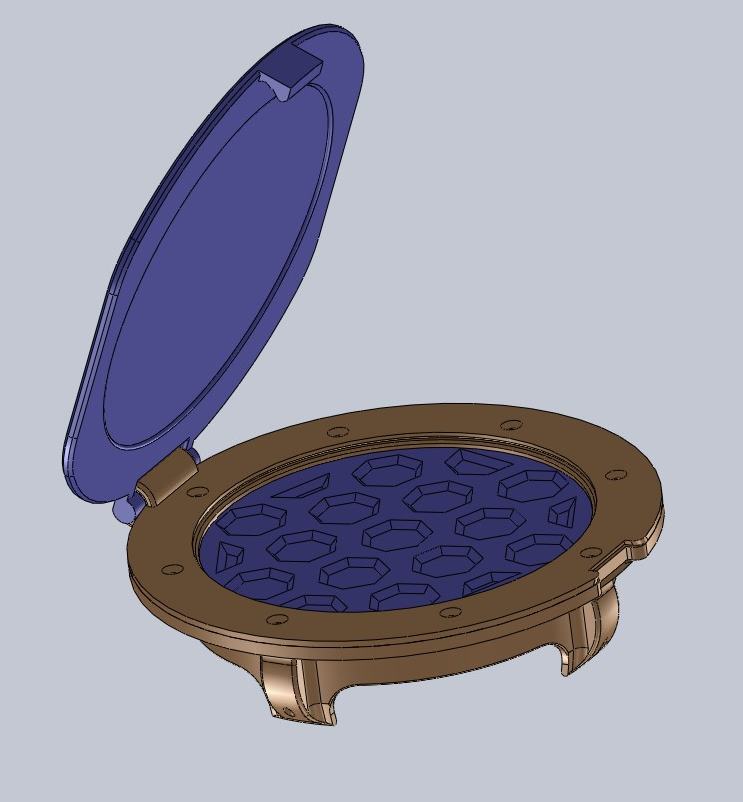

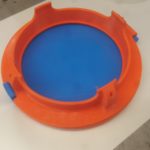

The telescope is a Skywatcher 80ED diffractor. The film holder was designed to slide snugly over the end of the telescope such that there would be no fear of it falling off. The four tabs curve inward and add a healthy amount of friction. The cap and plug are for safe storage of the film. There is about 3 mm of clearance between the film and the cap / plug, which should be plenty to prevent contact.

All parts were 3D printed except the screws. The STL files can be found at https://www.thingiverse.com/thing:2497478 Blue parts were printed in PLA (faster and cleaner printing) and the orange parts in PETG (Added flexibility). Assembly was performed carefully but was relatively easy. Countersunk M3 screws were used and self-tapped into the body. Prior to final assembly, the body and clamp were temporarily assembled and the hinge was drilled out to clean up the print.

The unusual pattern on the cap and plug have three purposes: decreasing filament usage, adding texture, and (most importantly!) allowing the print to be removed from the print bed easier. Solid printed faces on the print bed are more difficult to remove, which can result in warping the prints during removal.

Tyler,

First, thanks for posting this design. However, my need is slightly different. I’d like to create this for the Evostar 72ED which has a 90mm lens shield instead of the 120mm lens shield of the Skywatcher 80ED. On the surface, it seems that scaling the design down to 75% this size would do the trick but what appears to be a potential problem is the corresponding reduction in thickness, at least for the cover and plug. Unfortunately, I’ve never worked with mesh designs before. Any advice on making the necessary mods to scale your design down?

Thanks,

Nate

Hi Nate, thanks for the feedback! To be honest, I don’t know how to modify the .STL properly either. I could modify the original Solidworks design thought, let me try find it (this is an old project so I’ll need to dig…). Comment again in a few days if I forget!