You Get What You Pay For

While building my CNC mill, I bought a 500W spindle with a motor controller off eBay for less than $80 CAD. The spindle and power supply needed some TLC right out of the box, but seemed to work fine.

Then the incident happened… I was adjusting the ‘MAX’ potentiometer when suddenly the motor speed dropped to 5,000 RPM and wouldn’t increase! I may have accidentally shorted the potentiometer with my screwdriver, but that shouldn’t have caused a problem. This potentiometer is basically shorted to 0 ohms at one end anyways.

No adjustments to any of the potentiometers would change the motor speed more than a few hundred RPM. I considered buying a replacement controller, but for $50 CAD I decided to have a crack at repairing this unit. I ended up writing an almost-complete schematic of the controller and determining what one of the three IC’s are.

Schematic for 500W Spindle Controller / Power Supply

The Undocumented Motor Controller

As I expected, the motor controller did not come with any documentation. Nobody seems to have a schematic online! I was browsing eBay, and noticed some controllers that look similar (identical?) and were rated for 300W. The eBay listing for my controller says it can output 0 – 100V and 6A, but now I’m suspicious. An under-rated motor controller would explain all the resetting issues it has caused in the past!

During my repair, I also spent some time trying to figure out if this controller is good to handle 500W. TLDR: The semiconductors are ok, but the capacitor might be too small.

They Removed The Model Numbers!

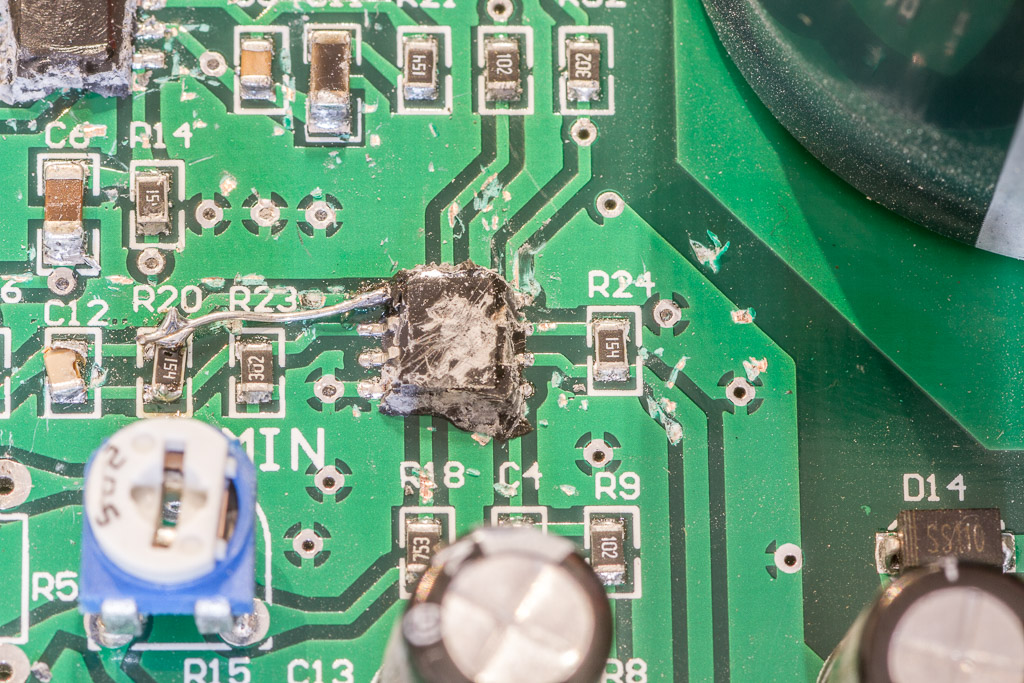

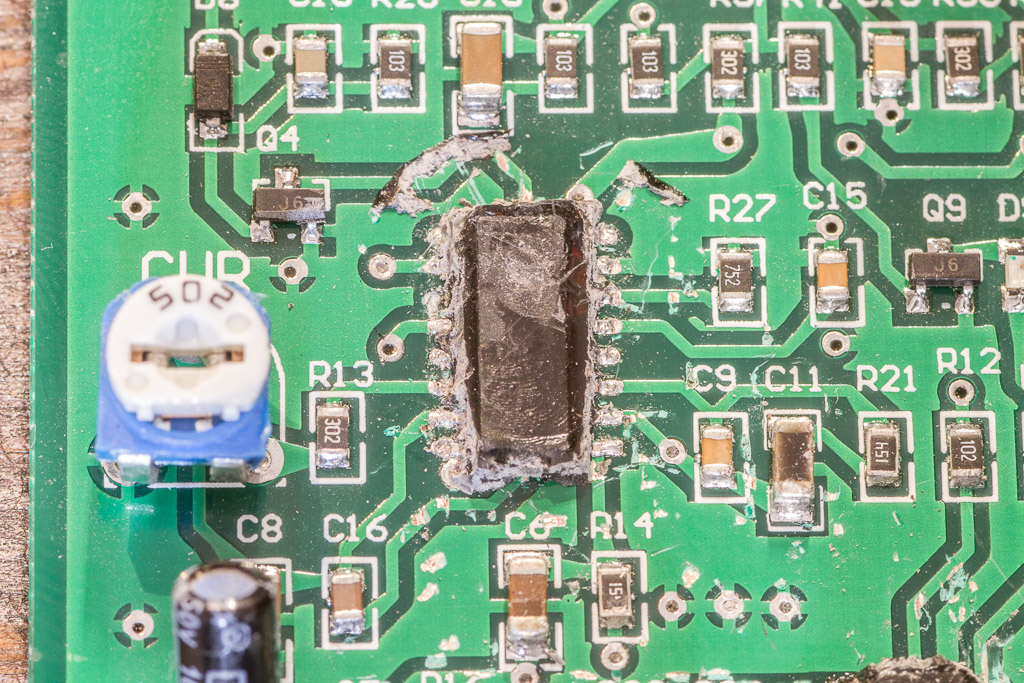

I had already cracked the case open and found a big blob of potting material on the board. It looked like the manufacturer was trying to hide the IC model numbers. A third IC wasn’t covered with the goop, but the model numbers were scratched off.

I wanted to reverse engineer the entire board in order to understand the problem. I used a torch to heat a knife and picked away at the blob for about an hour. In the process, I uncovered most of the traces, accidentally knocked off a resistor, capacitor, damaged a trace, and ripped off an IC pin (which lead to an interesting discovery – keep reading). I replaced the resistor and repaired the trace, and the controller then worked just like before the blob was cut off.

Unfortunately the IC model numbers were still indiscernable! I had to do some sleuthing to figure out what they were. I started by creating a circuit diagram.

The Circuit

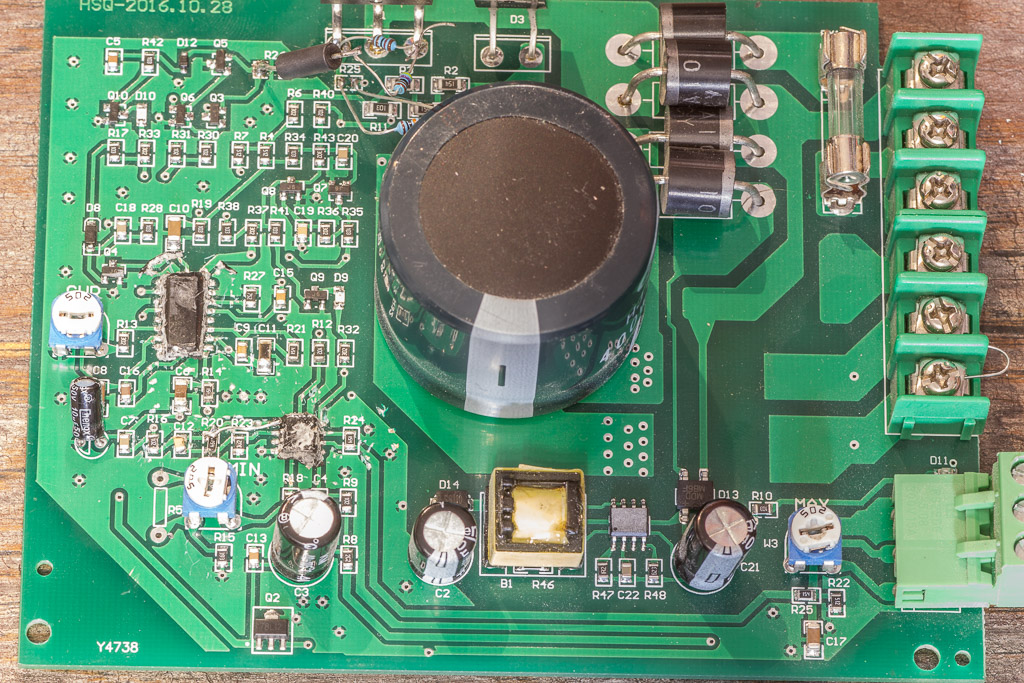

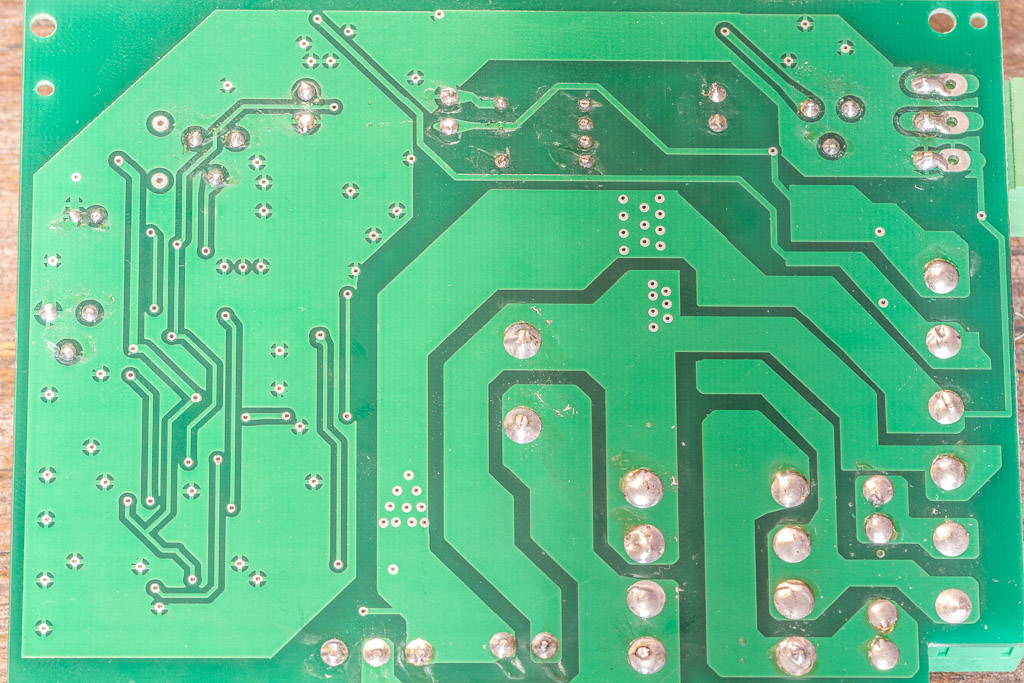

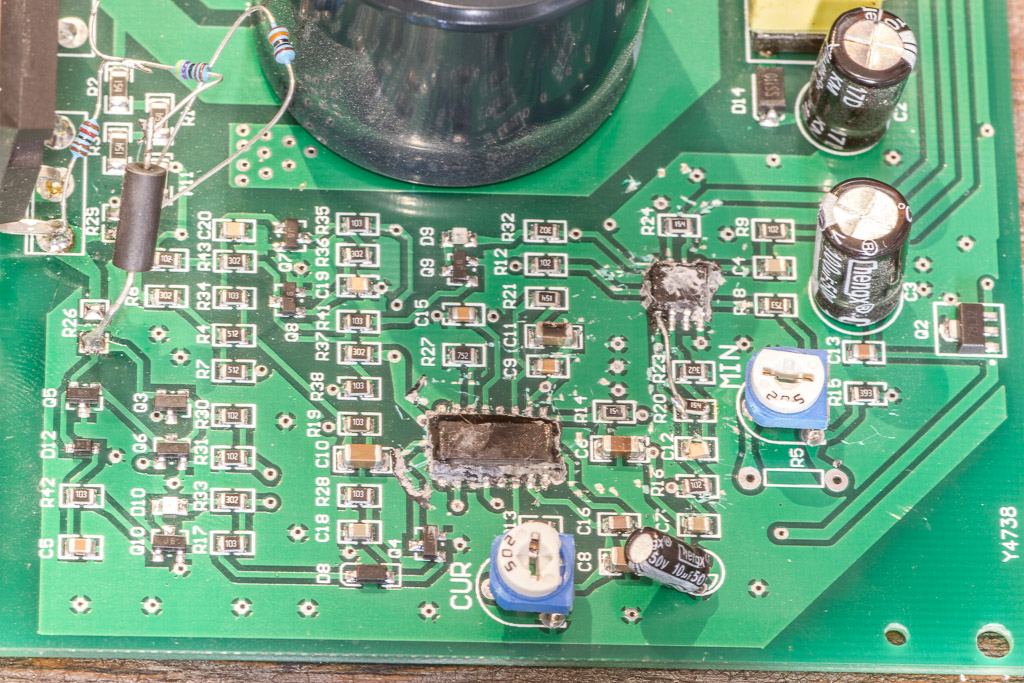

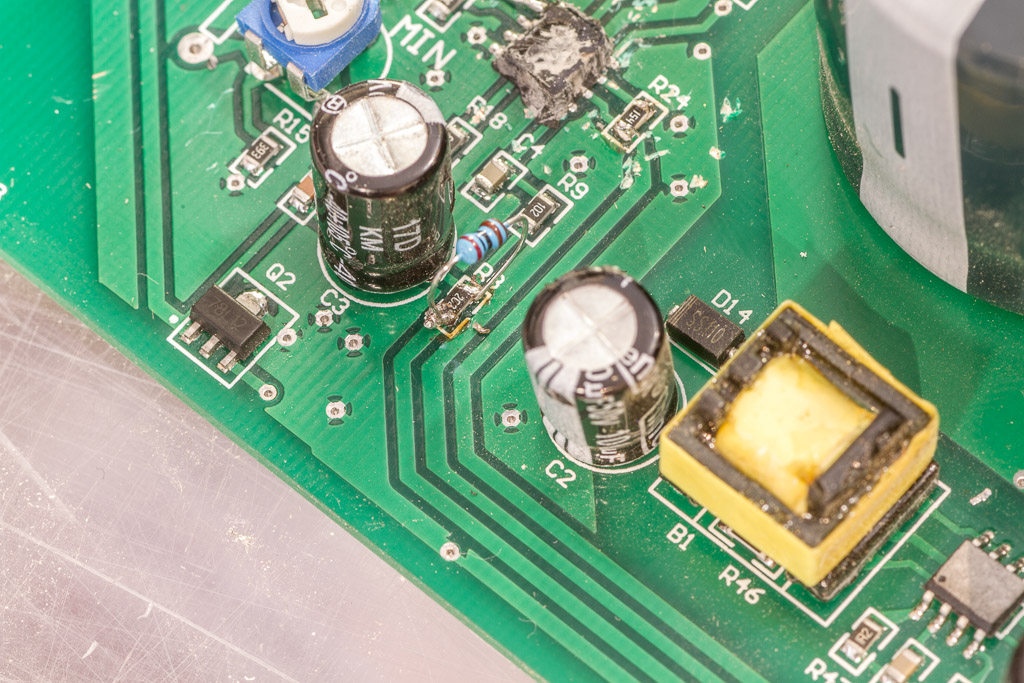

Here are some photos of the board. The rectifier and switching elements are on the central and top right section, the 12V flyback converter is near the bottom, and the PWM control circuitry is on the left.

The main rectifier diodes are in a row next to the AC input fuse. The 330uF capacitor in the middle smooths out the rectified power. The isolation transformer is… absent. So the output power is NOT floating!

The main rectifier diodes are in a row next to the AC input fuse. The 330uF capacitor in the middle smooths out the rectified power. The isolation transformer is… absent. So the output power is NOT floating!

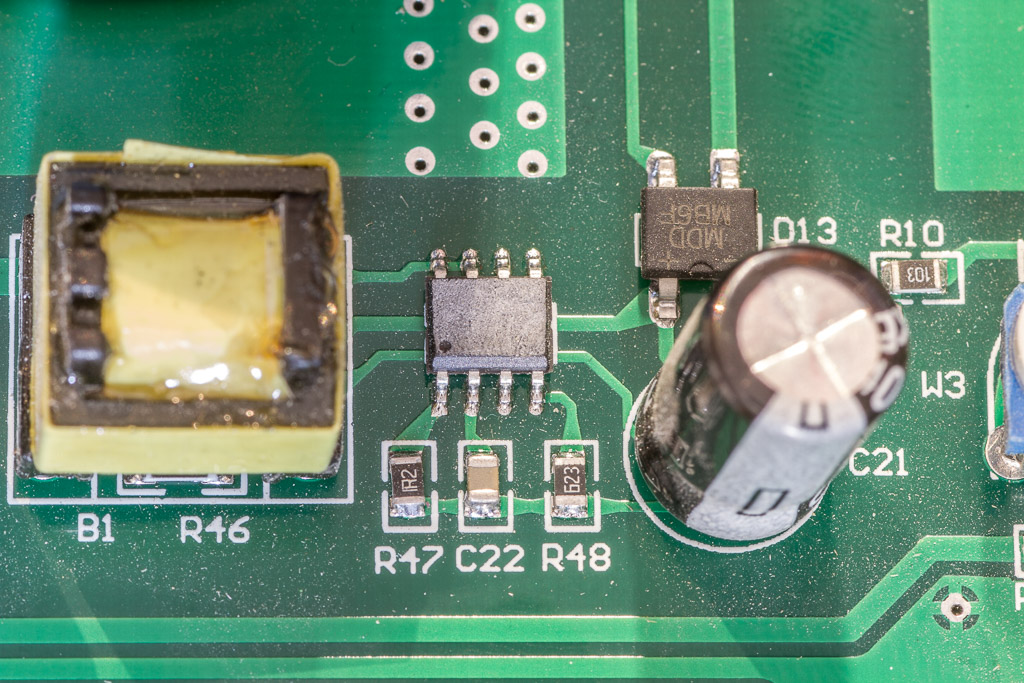

The ground poor for is actually tied to the PWM MOSFET’s drain. The control voltage is provided by a second rectifier and a flyback transformer (shown below). The model number of the flyback controller is scratched off, but the output is connected to a 78L12 linear regulator to provide +12V.

The ground poor for is actually tied to the PWM MOSFET’s drain. The control voltage is provided by a second rectifier and a flyback transformer (shown below). The model number of the flyback controller is scratched off, but the output is connected to a 78L12 linear regulator to provide +12V.

There’s a SOIC-8 chip connected to the MIN, MAX, and SPEED potentiometers. I’m not sure what it is, but best guess is an op-amp. I damaged the trace coming from the number one pin and had to repair it. The spindle did NOT work until I made the repair.

Using the circuit diagram, I searched Digikey for buck controllers in a SOIC-16 package and found three potential candidates for the larger IC: TI TL494, TI TL494, or Diodes Incorporated AZ7500B. Interesting how these parts from two different manufacturers have the exact same pinout…

Using the circuit diagram, I searched Digikey for buck controllers in a SOIC-16 package and found three potential candidates for the larger IC: TI TL494, TI TL494, or Diodes Incorporated AZ7500B. Interesting how these parts from two different manufacturers have the exact same pinout…

Note how I destroyed the #11 pin (the package is photographed upside-down). In the datasheets, this pin is intended to be connected to pin #8 so that the internal BJT’s are in parellel. It would seem that I may have knocked off a redundant pin. Lucky!

Note how I destroyed the #11 pin (the package is photographed upside-down). In the datasheets, this pin is intended to be connected to pin #8 so that the internal BJT’s are in parellel. It would seem that I may have knocked off a redundant pin. Lucky!

I also had a look at the MOSFET and flyback diode to see if they could handle a 5A, 100V inductive load.

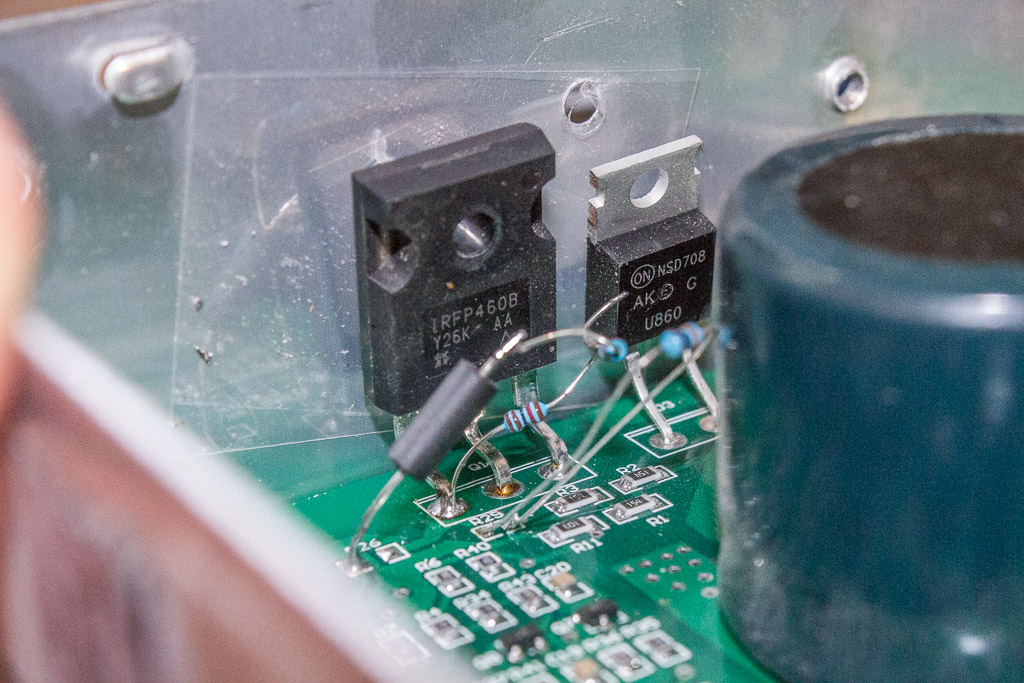

The switching element is a Vishay IRFP460B N-Channel FET. Its rated Vds is 500V and its Id is 13A. At first glance, these look good. I searched for an NSD708 diode, and instead got a listing for a Motorola MUR820/840/860 Diode. It’s in a TO-220 package, polarity is correct, and the bottom of the diode says ‘U860’ so I think this may be our diode. Peak repetitive forward current is 16A and peak repetitive reverse voltage is 600V for the MUR860. This is an ultrafast schottky diode, so I think it should be good for the job.

The switching element is a Vishay IRFP460B N-Channel FET. Its rated Vds is 500V and its Id is 13A. At first glance, these look good. I searched for an NSD708 diode, and instead got a listing for a Motorola MUR820/840/860 Diode. It’s in a TO-220 package, polarity is correct, and the bottom of the diode says ‘U860’ so I think this may be our diode. Peak repetitive forward current is 16A and peak repetitive reverse voltage is 600V for the MUR860. This is an ultrafast schottky diode, so I think it should be good for the job.

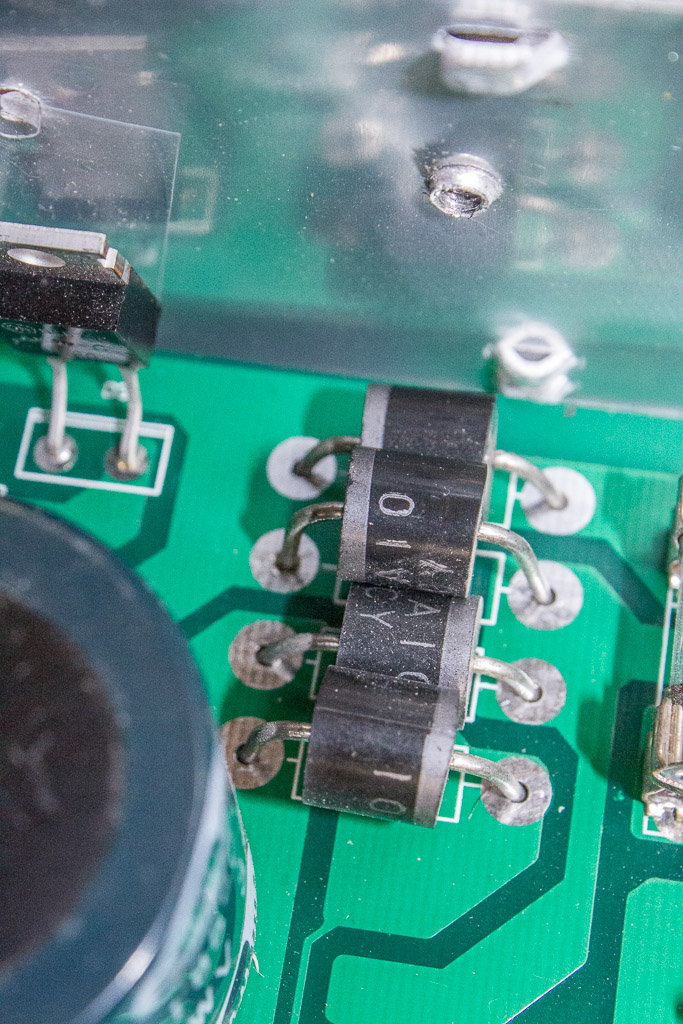

The rectifier diodes look pretty bulky. I should check the forward voltage when it is on…

The rectifier diodes look pretty bulky. I should check the forward voltage when it is on…

The Repair

I admit failure in that I never discovered what had changed or become damaged on the board. However, I did return the board to its original function by adding only one resistor! R8 is a 2K resistor, and I simply added a second 2K resistor in parallel. This increased the voltage to the SPEED potentiometer!

You can see the repair in the schematic. My guess is that a voltage reference or some other semiconductor became damaged when I shorted the potentiometer. Maybe it was caused by a quick voltage fluctuation? If you have an educated guess, please leave a comment!

Next, I had to set the MIN and MAX potentiometers. I did this using a laser tachometer to set it to 3,500 – 12,000 RPM.

Time to put everything back together!

Thanks for reading!

Last Updated 2019-11-30

Thank you so much for posting this especially the schematic. I’m pretty noob when it comes to electronics and managed to break two of these power supply. I hate to post the whole story here since I feel like an idiot for not learning from the first board that i damaged. Would it be possible to explain in email?

Hey Rick, sorry to hear that… Definitely! tyler@td0g.ca

Right after I posted the second comment, your response showed up. If I can explain further please let me know. I have posted a brief description on my second comment.

Appreciate the work you put into creating the schematic. I was wondering if you can help me get started on what to look for. I managed to damaged two of these boards due to “noobness”. I connected a toggle switch to the On/Off terminals. The toggle switch have a third ear for ground so I connected that to the case. I connected the “earth” wire from the 110 power source to the case as well. This broke something but I have no idea what. Visually, there’s no sign of burn. There’s no reading on the motor terminal with a volt meter when the pot is turned all the way up. Can you help? I have a third one on order so I have two to work with. Thank you.

Hello .. Can you help me clarify more (not on the site) the schematic and draw it better with the names of the electronic parts on it

Hey Ome,

I’m not sure what all the parts are. I wrote about them in the blog post. What part would you like to know?

Tyler

Hello .. Can you help me clarify more (not on the site) the schematic and draw it better with the names of the electronic parts on it

Hey there, I might be able to help out a bit. My email is tyler@td0g.ca if you like to email me.

I had same board …but one rectangular shaped 5l*1b*4h in cms…with 13 pins ..not mentioned any name on that ….can u tell me that part name please

Unfortunately I don’t know what all the parts are. Sorry! If you read the entire post, I have some guesses…

Hello.. did you still don’t know the model number of IC1 my power supply IC1 is burnt and i cant fix it because don’t know the name of it.

Hello, it is BP9201A.

IC1: BP9021A

Bonjour il m’est arrivé une mésaventure avecun bloque d’alimentation similaire a celui-ci. Une resistance a cramée .

Sur la photo ou vous dite :”Il y a une puce SOIC-8 connectée aux potentiomètres “ma resistance (r47) a brûlée comment cela et’il possible et comment puis-je réparer cela

Merci a vous .

Hi, in my board, U1 (small switching circuit for 12v power) is BP9201A.

Trying to find where could an external PWM be coupled into board (CNC controller 12V PWM output).

hi guys i wonder if anyone can help me out here

i have the same power supply. it even has the same black resin mark on it lol

anyway i pluged my spindle in the other day and the neutral wire came loose and arced of the live wire

so i opened it up and saw no visible damage so i pluged it in and it worked for 3 mins then shut off and restarted a few mins later

the capacitors are fine fuse is fine i looked online how to test the mosfets and they seem fine

so it looks like it is getting to hot and shutting down

any help would be much apreciated

Excellent work @td0g indeed.

Any idea on how can we control the speed not by the potensiometer but from UNO CNC shield and GRBL?

Looks that an isolated circuit is needed but before I design one I like to know if someone else did it.

Thanks

After some tests, I identified that in fact the IC2 is an operational amplifier, I successfully replaced it with an LM358 SO-8.

thanks for your help. for wonder full schematic and analysis. I have a Stepper motor driver DM542 can we work together to analyze that all ic number are usually removed but luckly to got Board With all IC number but difficulty is that it is using TMS microcontroller. Is there anyone who have idea to work on that microcontroller

Not sure if it’s helpful but the Q1 component is a 78L12, a 12V regulator.

Hello, I have just repaired this power supply, the double AOP LM358 had a defective side, which discovered the PCB and I corrected your diagrams (3 diagrams attached). The PWM controller was reversed. It should be noted that the +12V is isolated from the + Motor. It is difficult to fully understand PWM management. Thank you for your work. Translation from French via Google translate.