Preamble

Converting a toaster oven into a reflow oven isn’t a new idea. I have to credit DJ Legion for bringing it to my attention. What makes this oven unique is its ‘Rapid Delivery’ system. No need to walk over to the over and remove the parts when it is finished!

Hardware

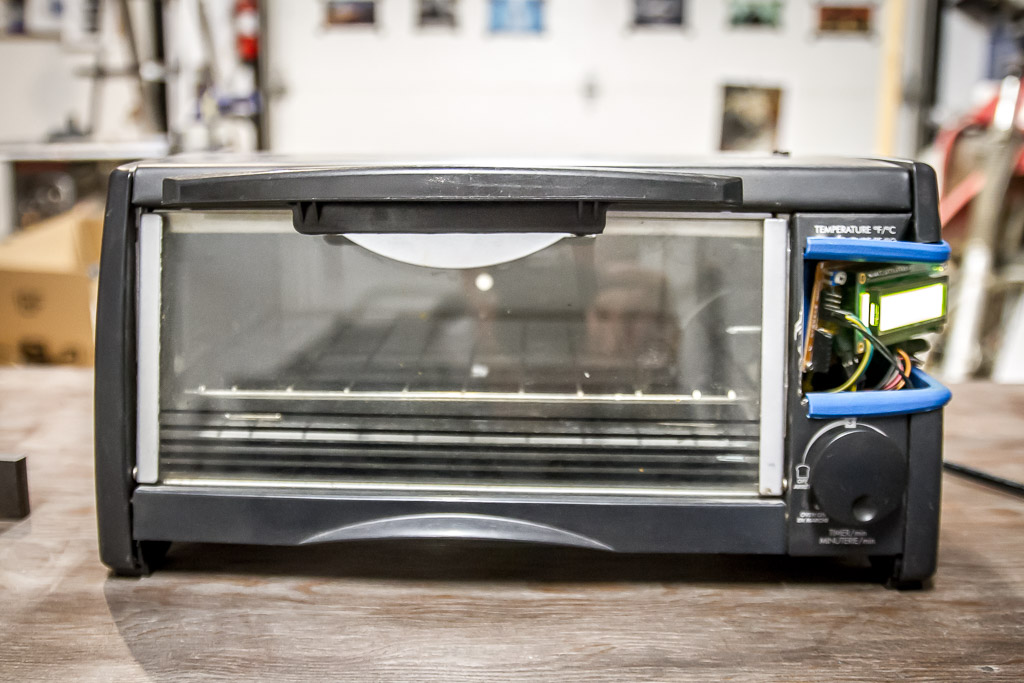

I stopped by Value Village and bought a used toaster oven. Not much more to say about that…

The electronics are a bit more interesting. I thought that some opto-isolated relay modules from eBay would handle the load for a while, so I wired them up. The circuit was clever and the two heating elements could be turned on in parallel (100% power), series (25% power), or on element on at a time (50% power). That way, the relays wouldn’t need to switch so often. Or so my theory went…

In practice, the relays lasted for one switch cycle. Then they became stuck and wouldn’t switch! Don’t trust the ratings on relays from eBay! Something something captain obvious…

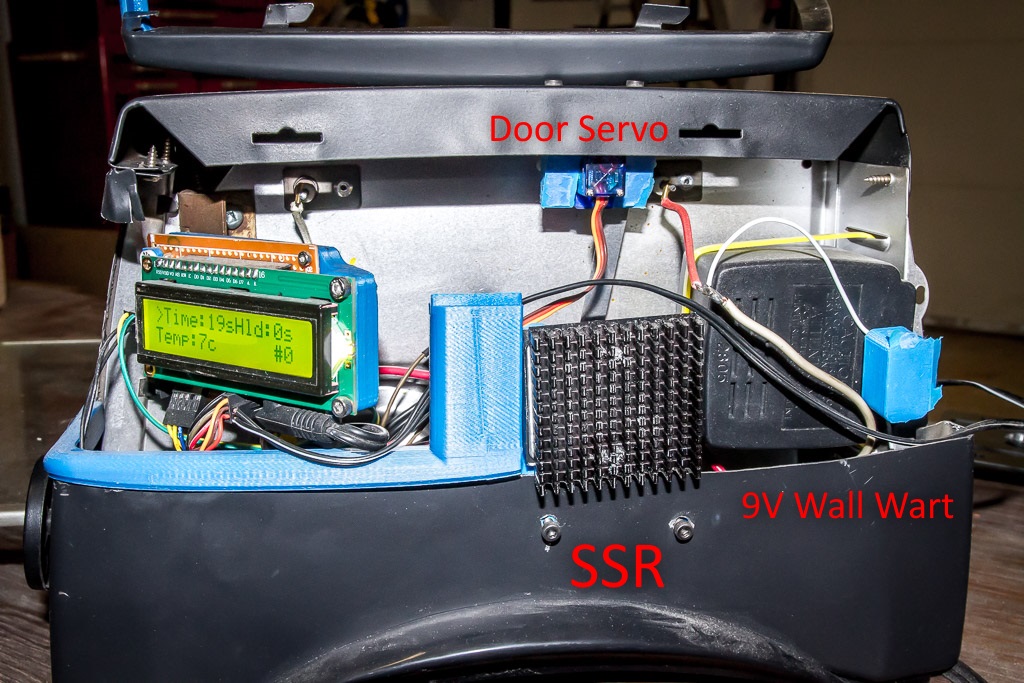

The proper way to switch the heating elements is with a Solid-State Relay (SSR). My understanding is that cheap SSR’s are prone to failure, and will often close when they fail (turn on 100% and won’t turn off). Not something I wanted to deal with! So I broke down and paid $45 for an Omron G3NE-220TL-US DC5 Solid-State Relay (SSR) from Digikey. The SSR is PWM’d and a PID algorithm controls the duty cycle.

The controller is powered with a 9V wall adapter. An onboard 7805 regulates the power

Automated Door

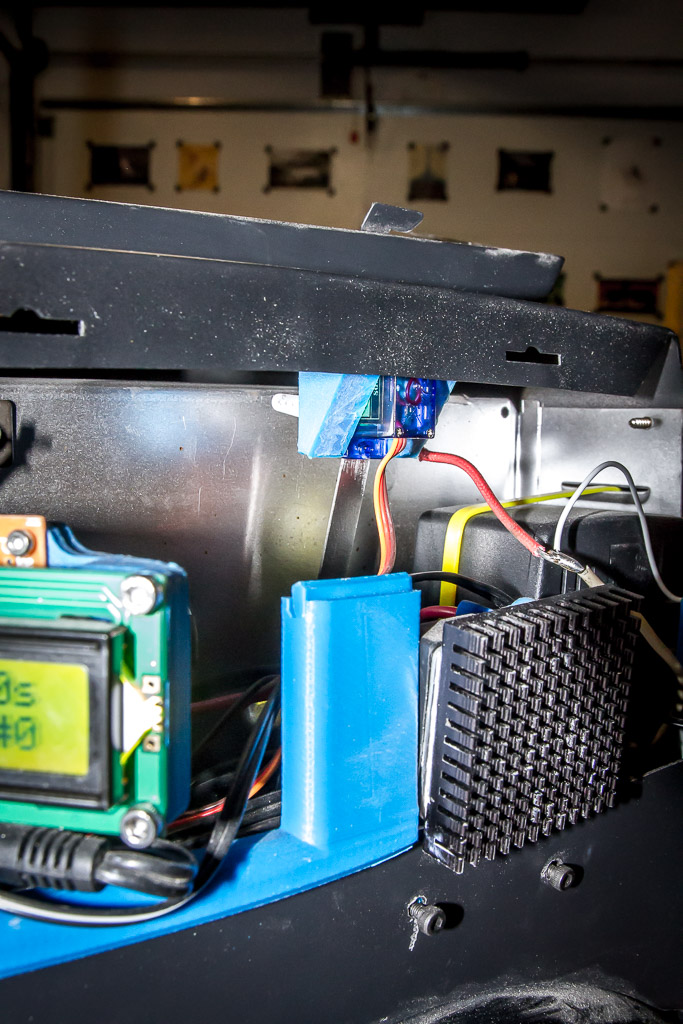

In order to rapidly cool the oven, I motorized the door. It uses a 9g servo with a large lever to increase force. The linkage worked well right away! I’m always surprised when such things happen.

The interesting bit was the firmware’s function to control the servo. To open the door a little bit, the servo must first open the door wide, then relax it back. Otherwise the motor will not be able to move the door such a small amount and will stall out.

Also, the servo must move slowly when opening the door wide or else it will throw the door all the way open! I decided that was a nice feature, and the firmware can command the door to open entirely when it is finished running a program.

After developing the automated door, I was taking a walk when the Rapid Delivery feature suddenly occurred to me. Eureka!

Deliverating The Goods

I developed a spring-loaded sweeper which can be setup inside the oven. The spring is quite strong, it takes both hands to set it.

The sweeper arm won’t go flying out of the oven because it’s attached to the spring, which is held onto the heavy rear block. A 1/4″ UNF screw holds the spring compressed, but releases after 1/4 turn. See the photo below.

A plastic gear-motor attaches to the screw on the back of the oven (through a hole) and is controlled by a TIP120 transistor on the control board. The 9V power supply drivers the gear-motor.

It the Rapid Delivery feature is enabled (which it is NOT by default) the oven will sound an alarm, throw the door open, and fling the oven’s contents at the user. Unfortunately, the grating inside the oven usually stops the contents from ejecting properly (in the video above, I put a piece of paper under the board to let it slide better).

It’s also useful for snacks. I’ve entertained a number of kids by serving ‘Throwed Pie’ and other deserts!

Firmware

I will admit that I’ve never used a ‘real’ reflow oven, so the firmware may be a little unusual. It uses the Ryan Downing’s AutoPID library for the heater control.

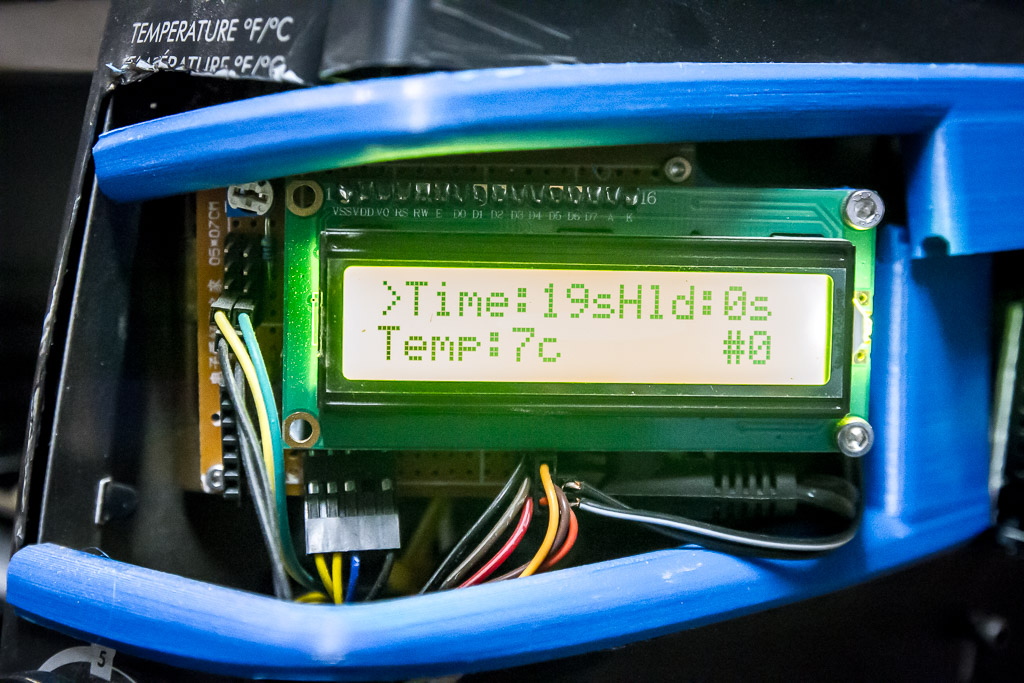

The UI uses an encoder and a 1602 LCD display. There’s a settings menu (to set the parameters for the PID algorithm), a program setup menu, a program run option, and a program recall menu. It’s available on Github for anyone interested.